Molding Sand: Types and Properties [PDF] - LEARN …

Dry Sand: Dry sand is the type of green sand, from which moisture is being removed. Dry sand is made by baking or drying the mold made from the green sand in a decent oven. The dry sand contains a mixture of 15% to 20% of clay and silica. This sand has more rigidity, thermal stability, and strength. The casting of the dry sand is heavy and large.

Sand casting - Wikipedia

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries.Over 60% of all metal castings are produced via sand casting process.

Molding Sand: Constituents, Types and Properties …

Silica sand in form of granular quarts is the main constituent of molding sand having enough refractoriness which can impart strength, stability and permeability to molding and core sand. But along with silica small amounts of iron oxide, alumina, lime stone (CaCO 3 ), magnesia, soda and potash are present as impurities.

Molding sand - Wikipedia

Molding sand, also known as foundry sand, is a sand that when moistened and compressed or oiled or heated tends to pack well and hold its shape. It is used in the process of sand casting for preparing the mould cavity.. Green sand. Green sand is an aggregate of sand, bentonite clay, pulverized coal and water.Its principal use is in making molds for metal casting.

SAND CASTING LESSON FOR BEGINNERS - YouTube

28-6-2016 · A Detailed Video Aluminum Casting Lesson Covering Everything You Need To Know As a Beginner Metal Caster To Get Started. A Start to Finish Video. Starting With An Idea and Casting Up a Finished ...

How to Easily Make Green Sand for Aluminum …

1-1-2014 · Here is an easy instructional video and recipe for making Green Sand at home. Use Green Sand for casting aluminum and other metals.

Sand Casting | Metal Casting Resources

Sand casting is a process that utilizes non-reusable sand molds to form metal castings.It is a common production method for metal components of all sizes, from a few ounces to several tons. Sand casting isn’t only versatile in the size of its products – it can also create exceptionally complex or detailed castings, and can be used to cast nearly any metal alloy.

Molding Sand: Constituents, Types and Properties • …

The general sources of receiving molding sands are the sea shores, rivers, lakes, deserts and granular elements of rocks. Molding sands can be classified mainly into two types namely natural or synthetic. Natural molding sands contains sufficient amount of binder material. Whereas synthetic molding sands are prepared artificially using basic sand molding constituents (silica sand in […]

Moulding sand - LinkedIn SlideShare

Moulding sand 1. MOLDING SAND MOLDING SAND By: Samir JariwalaBy: Samir Jariwala 2. MOLDING SAND Molding sand are the most commonly used for making all types of molds irrespective of whether they are used for producing casting of ferrous or non-ferrous metal Most sand casting operations are used silica sand. Sand used to manufacture a mould for casting process is held by mixture of water …

China Sand Molding Machine, Sand Molding …

China Sand Molding Machine manufacturers - Select 2020 high quality Sand Molding Machine products in best price from certified Chinese Sand Casting Mold manufacturers, Foundry Molding Machine suppliers, wholesalers and factory on Made-in-China.com

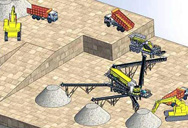

Types of sand casting tools and equipment - …

Flasks are commonly used for preparing sand molds and keeping molten metal. The followings listed below are types of sand casting tools: 1. Hand riddle: is a type of foundry tools generally used for cleaning sand. They are used for separating sand and another object …

Mixing molding sand (greensand) - backyard. …

Mixing molding sand (greensand) Based on some of the e-mails I get there are plenty of people having trouble with their molding sand.I put this page together to illustrate just how easy it is to make a small batch of greensand for your personal foundry.

Green Sand Formula - How to Make Molding Sand …

Green Sand Formula - How to Make Molding Sand: To makegreen sand or like it also called molding sand (foundry sand) we need 3 ingredients: sand, clay and water.

Types of Molding Processes | Sciencing

Different types of molding processes form stone into the desired shape based on the plastic’s intended use. stone manufacturing relies on different types of molding in a variety of shapes. stone is a synthetic material that is soft or semi-liquid when hot. The soft stone is placed in …

Sand Casting Process Basic Concept and Procedure …

Sand Casting: The sand casting process also called as sand mold casting. It is a common method for metal casting. Almost 70% of metal casting of product follow by sand casting process. The bonding agent (clay) is mixed with the sand. The mixture is moisturized with water for develop strength and plasticity of clay to make mold.

Foundry Sand Types - Dandong Foundry

Resin sand is a promising new type of modeling material, and at present, it is mainly used in the manufacture of complex sand cores. Since different sands have different advantages, in metal casting, we should adopt the right one to meet different needs. Clay Sand, Green Sand. Furan Resin Sand. Dry Sand, Water Glass Sand

How to Sand Baseboard Molding | Hunker

How to Sand Baseboard Molding ... Sand lengthwise along the baseboard in the direction of the stone stone using long strokes. ... A flexible sanding block made with a stone or foam core conforms exactly to the contours of baseboard molding. This type of block is …

What is the water content in molding sand? - Quora

I guess you mean green sand like an iron foundry would use. Green is not the colour of the sand, green means the sand is moist like green stone is. There are also molding sands that are meant to be dried with heat before being used for casting meta...

CN102728784A - Clay-type molding sand and …

The invention discloses a clay-type molding sand and a preparation method thereof. The method is as below: weighing raw materials of, by weight, 80-100 parts of recycling sand, 10-15 parts of chromite sand, 3-8 parts of pulverized coal, 1-3 parts of sepiolite, 10-20 parts of calcium bentonite raw ore, 1-3 parts of fine-grained magnesia, 0.5-1.5 parts of furan resin, 1-3 parts of flour, 2-4 ...

Molding (process) - Wikipedia

Molding or moulding (see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material.