Concrete Manufacturing Process in modern …

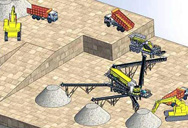

Concrete Manufacturing Process consists of many stages. The Concrete mix for delivery from a plant instead of mixing on the stone site. The concrete mixes, transports and delivers to a construction site to place in formworks for construction.

Manufacturing process | Lafarge - Cement, …

The cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays. A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km.

Concrete Production Process| …

We’ve created this guide to the concrete production, ordering and delivery process. Read on to learn more about how concrete is produced and the easiest ordering and delivery process for concrete. The Benefits of Using Concrete. We’re often asked how concrete compares to other building materials.

Concrete Production - an overview | ScienceDirect …

Concrete production is a highly intensive energy-consuming process and presently facing a number of challenges in reducing the carbon footprint and making it more economic. Sustainable technologies in maintaining concrete structures are proving to be a great challenge. Microbially induced carbonate precipitation (MICP) has developed as a novel and sustainable technique in improving the ...

what process of concrete production - …

concrete production process - kittycatpetsitting.co.za Eco-sustainable Geopolymer Concrete Blocks Production Process, FlorenceSWIF2015 Eco-sustainable Geopolymer concrete blocks, The process production, The Process for Making Portland Cement - Concrete, The Process for Making Portland Cement Materials that contain appropriate amounts of calcium compounds, silica, alumina and iron …

How Cement Is Made - Portland Cement Association

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to ready-mix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

PRECAST CONCRETE PROCESS - The Constructor

PRECAST CONCRETE PROCESS A large number of concrete structures (about 6% of the building frame market) are precast. The individual components are prefabricated off site then taken to site where they are erected. The following figures illustrate the precast concrete process: & Ad Free! EXPLORE VIP Membership 1.

Process of manufacture of concrete - LinkedIn …

Process of manufacture of concrete 1. ... BATCHING Batching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer . ... production of concrete at jobsite, or small quantities. Advantages: Combined materials transporter and batching and mixing system. One-man operation.

Production of concrete - LinkedIn SlideShare

Stages for production of concrete:- BATCHING MIXING TRANSPORTING PLACING COMPACTING CURING FINISHING 3. Batching:- Batching is the process of measuring concrete mix ingredients by either mass or volume and introducing them into the mixer.

Cement: Materials and manufacturing process

A ball mill is a rotating drum filled with steel balls of different sizes (depending on the desired fineness of the cement) that crush and grind the clinker. Gypsum is added during the grinding process to provide means for controlling the setting of the cement. The cement is bagged transported for concrete production.

IELTS Task 1 Process- Cement and Concrete …

Source: Cambridge English IELTS Past Papers. Question– The diagrams below show the stages and equipment used in the cement-making process, and how cement is used to produce concrete for building purposes.. Answer The diagrams illustrate the phases and apparatus to make cement and how cement is utilised in the production of concrete for construction.

What is the manufacturing process of cement? - …

Hi, Following three distinct operations are involved in the manufacturing of normal setting or Portland ordinary cement: 1. Mixing of raw materials 2. Burning 3. Grinding MIXING OF RAW MATERIALS The raw materials such as limestone or chalk and sha...

Cement: Production and Composition - YouTube

11-3-2014 · Concrete Technology by Dr. B. Bhattacharjee,Department of Civil Engineering,IIT Delhi.For more details on NPTEL ... Production at Ramco Cement Plant in India - …

Concrete Design & Production - Portland Cement …

Concrete does not even necessarily have to be directly exposed to the atmosphere for this process to occur. Underground concrete piping and foundations can absorb CO 2 from air in the soil, and underground and underwater applications might absorb dissolved carbon dioxide (carbonates) present in groundwater, freshwaters and saltwaters.