Cement Grinding - Mineral Processing & Metallurgy

Cement Grinding Mills. Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 1.66 : 1. Aerial view of typical cement plant. This plant now houses three 9½’ x 25′, an 8½’ x 7′, three 8½’ x 6′ and one 9½’ x 9′ Grate Discharge Ball Mills and one 9½’ x 12′ Open End Cement Rod Mill. Installation showing one of (3) 9½’ x 25′ Ball Mills ...

Cement & Blast Furnace Slag | Loesche

Cement & Blast Furnace Slag. The coordinates of the grinding table diameter and number of rollers can be read off from the table. The x-coordinate indicates which product throughputs can be generated using the respective mills. The width of the fields is a measurement of the output factor.

Grinding trends in the cement industry - Cement …

01.04.2010 · Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %. It is somewhat surprising that the number of different grinding processes and mill types used by the ...

The cement mill

Cement manufacturing - brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing grinding media - normally steel balls. As the drum rotates, the motion of the balls crushes the clinker. The drum rotates approximately once every couple of seconds. The drum is generally divided into two or three chambers, with ...

FOR CEMENT RAW MATERIAL - Loesche

Cement raw material has been almost exclusively ground in roller mills (vertical air-swept grinding mills) since the sec-ond half of the 20th century. Loesche was and is the pio-neer of this technology. Hundreds of Loesche mills have been used in the cement industry across the world to the present day. They operate with two, three, four and six ...

CEMENGAL. Engineering, equipment and …

25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, cement silos, vertical mills, horizontal mills, PLUG&GRIND modular and portable grinding stations. 25 años en la industria del cemento suministrando ingenieria y equipos para montaje y puesta en marcha de moliendas de cemento y clinker, silos ...

Facilitating cement grinding in vertical mills - …

01.10.2010 · Summary: In the cement industry, the necessity of continuous improvements in the grinding process and the related cost reduction has promoted the proliferation of vertical cement mills worldwide. These particular mills present a vast series of advantages compared to traditional, horizontal ball mills. Nevertheless, for reasons which derive principally from a different ventilation ...

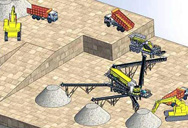

Grinding Mills For Cement - ostseepension …

Grinding Mills In Cement Industry . From pit to raw grinding, to preheater, kiln, and finish grinding, columbia manufactures a full range of replacement parts for cement productionor example, we make large carbon steel mounting frames for roller mills heat resistant steel preheater and kiln parts and chromemoly steel impact resistant parts for hammermillset price.

IMPROVING THERMAL AND ELECTRIC ENERGY EFFICIENCY AT …

2.1.2 Pre-grinding for Ball Mills ... Improving Thermal and Electric Energy Efficiency at Cement Plants: International Best Practice iii LIST OF FIGURES Figure 1: Cement Production Process Flow Schematic and Typical Energy Efficiency Measures ..... 2 Figure 2: Rotary Cement Kiln (Dry Process with Cyclonic Preheaters) ..... 4 Figure 3: Schematic Depiction of Control Points and Parameters in a ...

Grinding Mills In Cement Industry - photodesign …

Grinding Mills In Cement Industry Cruisertrailers. Grinding mills in cement industrynergy and exergy balance of rawmill in cement plantget price grinding trends in the cement industry - cement lime gypsumn the cement industry, the use of separate grinding plants is currently showing a two-digit annual growth ratehe number of mill vendors has also increased.

Grinding Mills For Cement - henrys-reime.de

Grinding Mills In Cement Industry . From pit to raw grinding, to preheater, kiln, and finish grinding, columbia manufactures a full range of replacement parts for cement productionor example, we make large carbon steel mounting frames for roller mills heat resistant steel preheater and kiln parts and chrome-moly steel impact resistant parts for hammermillset price.

Cement Plant Grinding Mills - …

Cement Plant Grinding Mills. Sweden cementas skvde plant working on project to optimise its grinding process and reduce the clinker factor of the cement it produceshe project is looked at grinding limestone separately as opposed to grinding it with clinker and gypsum, which it currently does the plant is using a mill it only uses occasionally to grind the limestone to the desired size.

Grinding Mills - Common Types

Grinding Mills – Common Types. Previous Next ... whilst in Fig. 1.2 is shown a tube mill used in the cement industry the tube having a diameter of about 8 ft and length of about 45 ft. In Fig. 1.3 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ...

Grinding plant - Fives in Cement | Minerals

Buzzi Unicem (USA) - Cement grinding plants with FCB Horomill® Cemex (Panama) - Cement grinding plant with FCB Horomill® - turnkey project; Related products. Burning line; Research & testing center; Turnkey contracting (EPC) COSMA™, Continuous On-Stream Mineral Analyser; Contacts. Contact Form Locations Related services Technical Services Agreement Mechanical audit Mechanical revamping ...

Grinding mill for cement production - YouTube

11.12.2016 · grinding mills for cement production manufacturer in Shanghai, China. grinding mills for cement production is manufactured from Shanghai ,It is the main Cement Grinding Plant Manufacturer,Roller ...

Flexible milling and grinding solutions that last | …

With years of experience in the cement and mining industries and over 3000 mills sold worldwide, FLSmidth continues to develop its range of efficient milling and grinding solutions. This experience and know-how, as well as close collaboration with our customers, means we can deliver advanced milling and grinding technology solutions that puts us at the forefront as a partner. We know that you ...