Copper Flotation - Mineral Processing & Metallurgy

Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually been improved to increase production while reducing operating and maintenance costs. Also, considerable attention is paid to automatic sensing devices and automatic controls in order to assure maximum metallurgy and ...

Copper Sulfide Flotation - Mineral Processing & …

Copper Concentrate Thickening and Filtering. The final cleaned flotation concentrate flows or is pumped to a Spiral Rake Thickener. A Adjustable Stroke Diaphragm Pump, mounted on the thickener superstructure, meters the thickened concentrate to the Disc Filter. The Thickeners are often used to store concentrates for filtration at fixed intervals.

Copper Ore Processing Methods

Copper Ore Processing Methods. Previous Next ... sulphide copper ores tables have been retained owing to unusual conditions at the plants or the smelters that treat the mill concentrates. The flotation process, ... are again subjected to flotation. The latter operation produces finished copper concentrate, ...

Copper extraction - Wikipedia

Copper concentrates produced by mines are sold to smelters and refiners who treat the ore and refine the copper and charge for this service via treatment charges (TCs) and refining charges (RCs). The TCs are charged in US$ per tonne of concentrate treated and RCs are charged in cents per pound treated, denominated in US dollars, with benchmark prices set annually by major Japanese smelters.

mineral processing ball mill for copper ore flotation ...

Ball Mill For Flotation Mineral Processing. Iron Copper Mineral Processing. Iron ore ball mill grinding mill 02 feb 2017 machine used to extract gold posted by 20170202 mineral processing technologymineral processing technology com offers mineral processing flotation cell products about 87 of these are min read. morethere will; Mineral Processing Equipment Manufacturers Ball

Evaluating Copper Rougher-Scavenger Flotation …

A modal examination of the products produced by the copper flotation rougher-scavenger circuit reveal important information regarding the limits to the efficiency of the process, imposed by mineralogy, fragmentation and flotation capacity. Let’s discusses various aspects of rougher flotation circuit performance and how to evaluate its results .

Acid Leaching Copper Flotation Concentrate

As an alternative to Acid Leaching, Copper Chalcopyrite (CuFeS2) concentrates are processed traditionally by smelting, which results in sulfur dioxide (SO2) emissions. The development of a hydrometallurgical process for recovery of metals from concentrates of Cu ores offers industry a low-cost, low-pollution alternative to the traditional pyrometallurgical practices.

Innovations in Copper Mineral Processing Technology

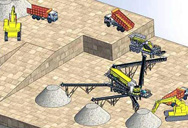

Reasons for Copper Ore Sorting • Pre-concentrate ore at mine: – Removes low-grade fraction that is uneconomic to process. – Reduces haulage costs. – Reduces grinding energy and flotation reagent costs. – Improves metal recoveries. • Monitor the mill feed which provides real time data to operators for process optimization.

Estimated Water Requirements for the Conventional ...

single copper concentrate has been modeled for this study. In 2011, approximately 13 million metric tons (Mt), or about 80 percent of the world’s primary copper supply, originated from concentrate produced by flotation (International Copper Study Group, 2012). In 2011, about 60 percent of primary copper produced in the United States ...

copper concentrate floatation tailings

Copper beneficiation methods and choose copper process. Dec 25, 2013Usually after the copper tailings is a sulphur concentrate. If in the ore gangue content more than 20% ~ 20%, still need again for sulfur concentrate separation. Get Price

copper concentrate flotation mill - …

Minto Mine Mill Operations Plan. The Mill Operations Plan (MOP) is a requirement of Quartz Mining Licence QML-0001 ... ore using conventional crushing, grinding, and flotation to produce copper ... ore containing copper, gold and silver to produce a copper concentrate in its...

Copper Crusher Copper Floatation Concentrate

copper crusher copper floatation concentrate Copper Crusher Copper Floatation Concentrate According to the natural condition, terrain and features of copper-molybdenum ore in Mongolia, our Fote specialists design the plant with machines like PE jaw crusher, PEX impact crusher, ball mill, spiral classifier, flotation machine and dryer, etc.

A Comparison Between a Flotation Mini Pilot Plant and a ...

A Comparison Between a Flotation Mini Pilot Plant and a Copper Concentrator Mill L M Loyola1 and K L C Gonçalves2 ABSTRACT In 1999, the Mineral Development Centre of CVRD (CDM) ... concentrate copper grade is 37 to 40 per cent and 0.3 to 0.4 per cent Cu for the final tailings.

Sulphide Flotation - an overview | ScienceDirect …

The concentrate tested was a flotation concentrate from the Northmet project, USA, assaying 14.7% Cu, 3.05% Ni, 0.14% Co, 26.7% S, 1.4 g/t Au, 2.2 g/t Pt, and 9.9 g/t Pd. Pressure-oxidation conditions were 225 °C, pulp density was 11%, retention time was 120 min, and oxygen overpressure was 689 kPa. The ore treated had a P80 of 15 μm.

Mill Operators’ Conference 2018 Nova copper-nickel project ...

(SAG) mill and an overflow ball mill in closed circuit with hydrocyclones. The ore is reduced to an 80% passing size of 75 μm. The cyclone overflow undergoes differential, sequential flotation to produce separate copper and nickel concentrates. Both flotation circuits are comprised of a rougher/scavenger flotation stage followed

DeGrussa Processing Plant overview - AusIMM …

The transfer size from the SAG mill was <100 µm which was much finer than design, and the target throughput rate of 187 tph was not always achievable. The SAG mill generated much more fines than the modelling indicated and this had detrimental effects on copper recovery in the flotation circuit.

copper concentrate flotation process equipment …

copper concentrate flotation process equipment crusher ... copper concentrate flotation process equipment crusher ... Mine Engineer.Com provides mining, gold, copper, coal, ... Mar 6, 2017 ... A Comparison Between a Flotation Mini Pilot Plant and a Copper Concentrator Mill.

APPENDIX 2: CAPITAL AND OPERATING COST ESTIMATE GR ...

The concentrate from the copper cleaners will be re-ground in a 132 kW stirred bead mill to further liberate the copper minerals. The regrind mill product will be directed to the copper recleaners for a f- inal stage of cleaning. The recleaning circuit will consist of five 1.9m . 3. conventional cells. Concentrate from the recleaners will be ...

Copper Concentrate Processing Equipment - Xinhai

The copper concentrate processing equipment needed in copper ore processing is complex because of the different property of copper concentrate. However, the main copper processing equipment for copper ore is same as other mining processing steps, including crushing, grinding, flotation separating and …