Recycling the Platinum Group Metal (PGM) - Refining Process

Global Refining Group: Leading the US With Our PGM Processing System. At Global Refining Group , we are confident that our processing system is the most effective method of PGM recycling in the United States and around the world. Capable of extracting 2 to 6% more material than any other current method, our completely enclosed processing system was created to exceed the current standard of …

Pgm refining | Johnson Matthey

Pgm refining. As the largest secondary platinum group metals (pgm) refiner in the world, weve developed highly advanced processes for extracting and separating pgms from products – so advanced that we can refine pgms to a purity of 99.95%.

PGM Refining Systems - Proses Makina

PGM Refining Systems. Process Machine Company present stone Refining and Recovery Systems for Precious Metals and Rare Metals. As everyone knows, Precious Metals means, gold, silver, platinum, palladium, rhodium etc. All of this metals easy to recover from any source such as E-waste, Spent Catalyst, Jewellery, Ore, Waste Liquid or Solid etc.

refining of platinum group metals / priciple flow sheet

refining of platinum group metals ore concentrate. pgm ore concentrate The figure below shows a typical assay of a South African platinum group metals ore concentrate obtained as the filter cake after sulfuric acid leach (according to the Sherrit process) of a Merensky reef converter matte.

Extraction and Refining of the Platinum Metals | Johnson ...

The complete process of extraction consists essentially of enriching this matte to approximately 65 per cent content of platinum metals and then treating this concentrate with acids to separate the individual platinum group metals from each other, followed by final refining.

Platinum Mining and Refining | Education

Refining platinum ore is a costly and laborious process. It can take from eight weeks to six months to process a batch of ore, and it can take up to 12 tons (11 tonnes) of ore to produce a …

Palladium Refining Tutorial - goldnscrap goldnscrap.com 2015

This is a refining process in which the initial feedstock is already of relatively high PGM content and has little to no presence of base metals. Recovered black PGM powder (AKA PGM black) can have a variety of sources; whether it is Catalytic Converters, Monolithic Ceramic Capacitors, Dental scrap or any other source, in which a recovery process is applied.

Extraction of Platinum Group Metals | IntechOpen

Processing of PGM involves comminution, flotation, smelting, converting, base metals refinery and precious metals refinery. Due to increasing chrome content in the feed and the challenges associated with operating high chrome feed, alternative routes to smelting of PGM are being investigated.

Industrial - Petroleum - PMM

Gasoline and stone feedstocks comprise mostly light fractions and so the refining process is largely devoted to converting heavy fractions into more useful lighter ones. Platinum is used in the processes known as reforming and isomerisation, which create the higher octane components for gasoline.

Metals Management | PGM Technologies

Routes of refining is PGMT’s expression for the readiness to suit the clients demand or a gauze producers’ inquiry with regards to the refining outlet. By origin the Circular Solutions approach is designed to reduce workload and efforts on the clients’ end.

PGM Refining - Accepted Materials Matrix

PGM Refining - Accepted Materials Matrix Material Pt Pd Rh Ir Ru Au Ag Comments Environmental Catalysts End of life autocatalysts Pre‐processed ceramic, metallic, silicon carbide Production residues Obsolete/reject stock

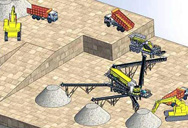

PGM Ore Processing

PGM Ore Processing The concept of project value tracking and its application in project planning at Anglo Platinum Flotation process optimization through frequent in-line grade measurement as an alternative to sampling surveys that deliver outdated results

Platinum Group Metals | Chem230 Wiki | Fandom

Before refining process, PGM is dried under high temperature to remove unwanted materials. Byproducts are oxidized and removed, and PGM is treated with air for the further concentration. Once concentrated, PGM goes through refining process. Eletrolytic technique is used to …

Umicore - PM / PGM refineries

PM / PGM refineries Umicore Precious Metals Refining has the unique capability to efficiently recover precious metals from all kinds of intermediates generated in primary PM/PGM-industry and PM/PGM-processing industry. These intermediates can originate from primary or from secondary metals processing, out of internal or of side-stream circuits.

Extraction and Refining of the Platinum Metals

ounces to the ton. The complete process of extraction consists essentially of enriching this matte to approximately 65 per cent content of platinum metals and then treating this concentrate with acids to separate the individual platinum group metals from each other, followed by final refining. Operations to achieve this can roughly be

PGM refining | Johnson Matthey - YouTube

Sep 24, 2018 · Category Science & Technology; Song Rising Thermal; Artist Matt Hill; Album ANW1009 - Modern Dance, Drum n Bass, Ambient; Licensed to YouTube by

Catalytic Converter Assays in the ... - Global Refining Group

Catalytic Converter Assays in the US & Beyond. As a wholesale supplier, you could be looking to sell catalytic converters per piece or on assay.If you are interested in the latter, Global Refining Group’s refining option is an ideal choice.

An overview of Southern African PGM smelting

An overview of Southern African PGM smelting R.T. Jones Mintek Private Bag X3015, Randburg, 2125, South Africa ABSTRACT The largest known platinum group metal (PGM) deposit in the world is the Bushveld Complex in South Africa, with the Great Dyke in Zimbabwe also being one of the biggest.